CHARACTERISTICS:

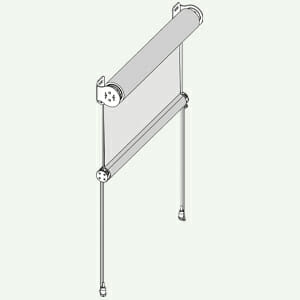

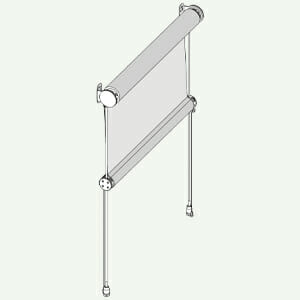

Application: vertical

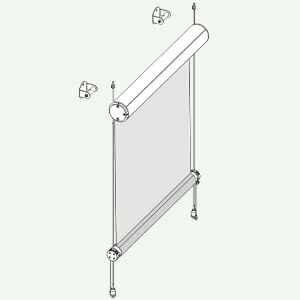

Installation: outdoors. Specially designed for an extreme adaptability during installation. The position of the mounting brackets and the distance between the wall and the cable guides may be adjusted on site, hence eliminating problems of slanted ceilings/walls

Brackets: 110×120 mm steel powder coated brackets and interior plates with PVC covers (white, grey, black). The angle of the interior plate can be adjusted at intervals of 22° to distance the cable from the wall. Supplement for AISI 304 stainless steel brackets

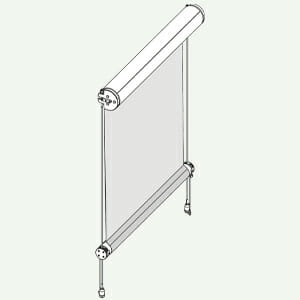

Roller tube: Ø 85 mm galvanized steel tube with slot to facilitate fabric removal

Side channels: Ø 4 mm, 19 strand stainless steel (AISI 316) wire cable guides

Hem bar with incorporated forced traction mechanism: FD60 Ø 60 mm extruded aluminium round tube with gas pistons, powder coated die-cast aluminium caps assembly with 33 return pulleys and AISI 316 stainless steel cable section Ø 2 mm, 49 wires. FD75 Ø 75 mm extruded aluminium round tube with gas pistons, powder coated die-cast aluminium caps assembly with 33 return pulleys and AISI 316 stainless steel cable section Ø 2 mm, 49 wires

Colours: white Ral 9010, silver anodised

Operation: motorised operation; 230V/50Hz M50 tubolar motor, with top/bottom limit switches and mains cable, thermal cut-out and class IP44 water resistance

Upper mounting: wall or ceiling

Lower mounting: stainless steel cable tensioning unit for floor mounting or, on request, stainless steel AISI 304 brackets for wall mounting